Contact Cleaning

Contact Cleaning

For cleaning even and firm materials with single- or double-sided continuous contact to the web.

Contact Cleaning

Where is web cleaning with contact to the material webs applicable?

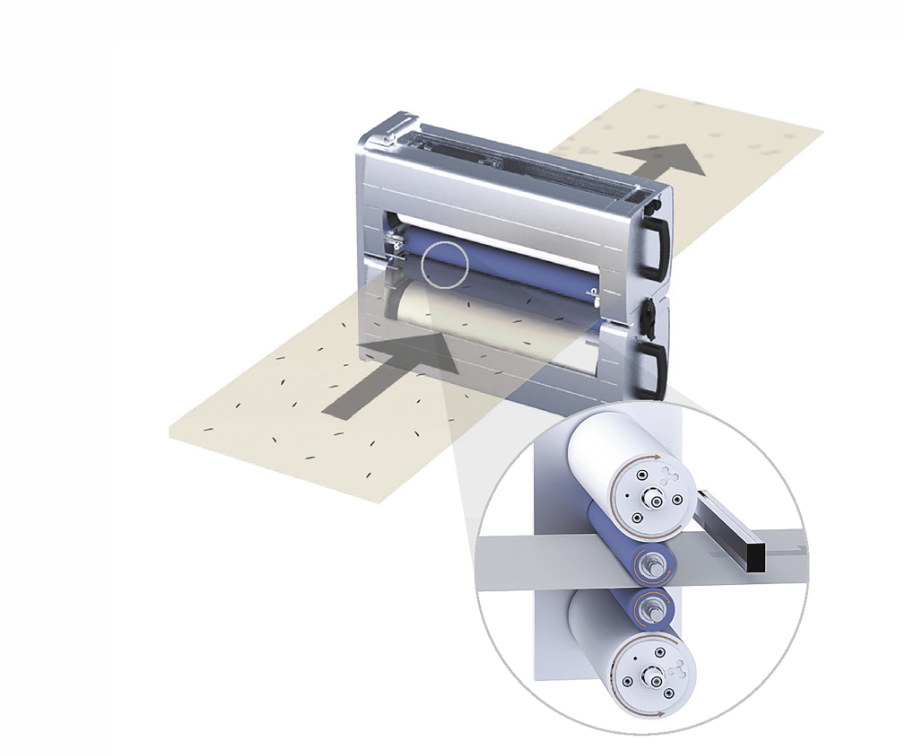

KELVA contact cleaners are suitable for removing contaminations on coated (glossed) paper, film and foil with low dust levels, web speeds up to 400 m/minute and web widths up to 2.500 mm. They are operated pneumatically and are available for cleaning of one or the two sides of the material web.

Specially developed polymer rollers lift and transfer contaminations from the web surface to easily replaceable adhesive sheets. The polymer roller is designed to give a very good contact to the web – even at low pressure. The active static discharger, located after the rollers, ensures that the web does not re-attract dust after passing through the cleaner.

Non Contact Cleaning

Non-Contact Cleaning

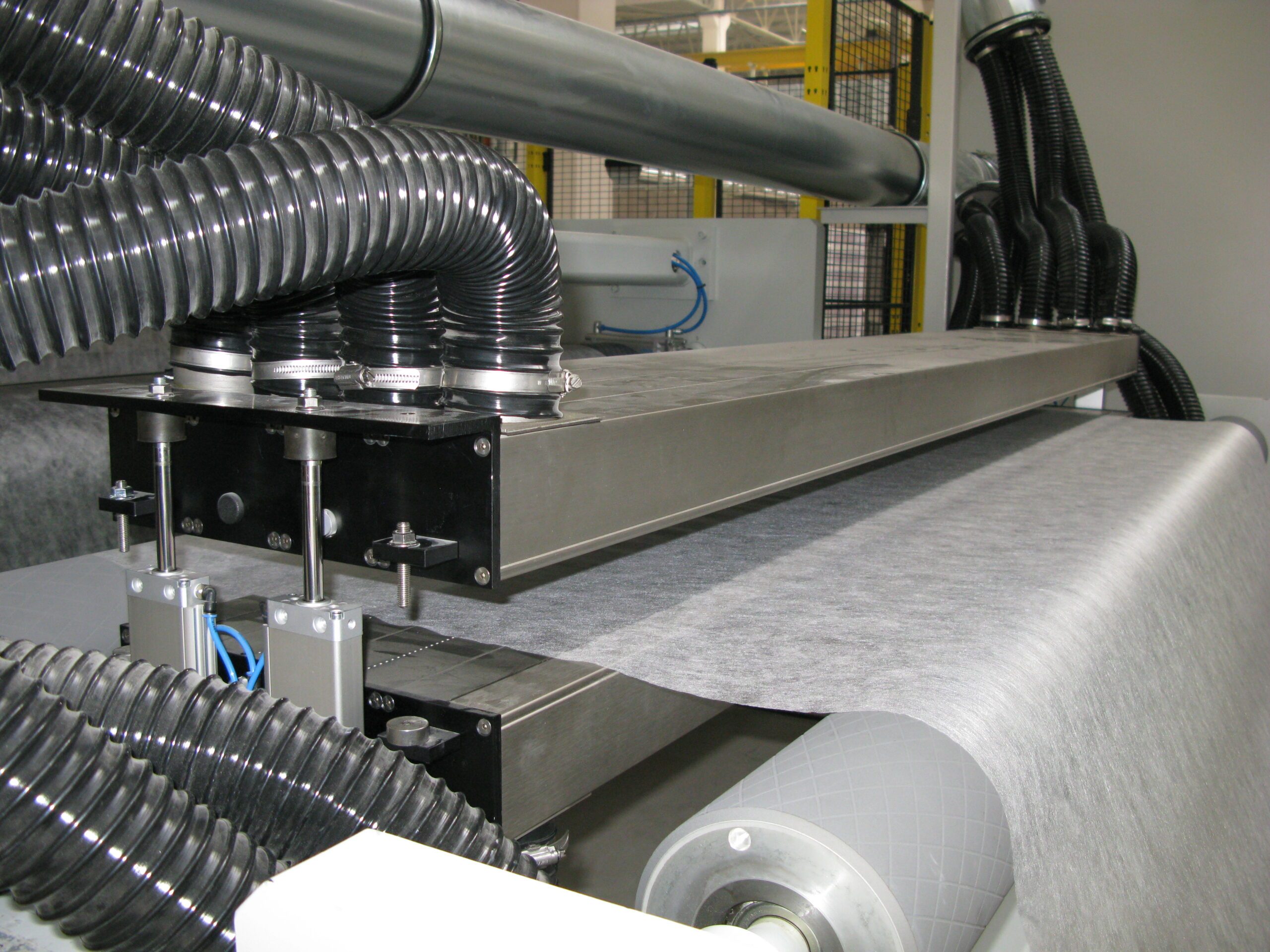

A wide range of non-contact web cleaning systems are available to cover web cleaning for various applications, such as paper, board, non-woven tissue, corrugated, glass, laminating etc. and materials in web widths from 300 mm to 10 m so far.

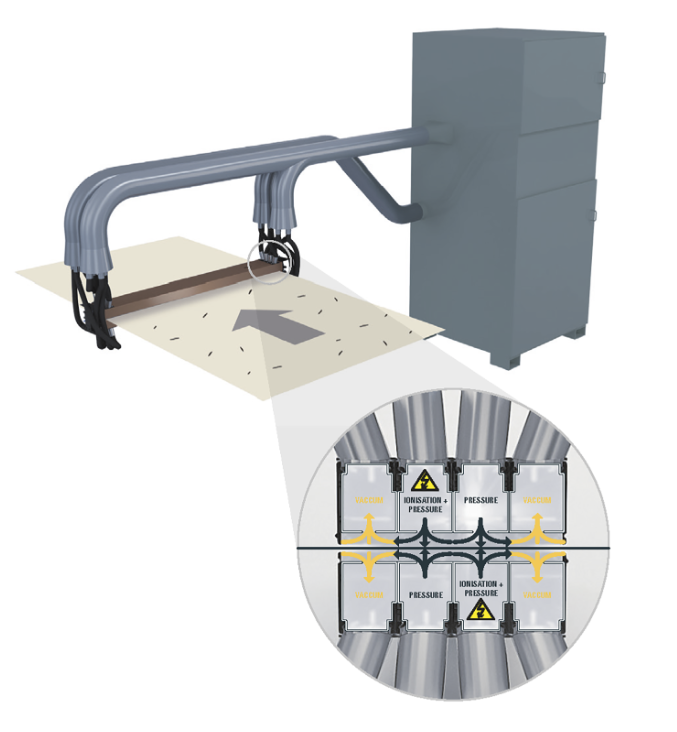

KELVA non-contact web cleaning systems with unique design

KELVA non-contact web cleaning systems with unique design

A KELVA non-contact web cleaning system comprises of a web cleaner head with integrated antistatic equipment, filter/ fan unit and connecting duct system.The unique design of the KELVA non-contact web cleaner allows the system to clean both sides of the web simultaneously. The cleaner neutralizes the static charge and breaks down the boundary air layer, which holds the contamination to the surface of the substrate. A combination of pressure air and vacuum creates micro-vibrations on the surface of the web loosening and removing the contamination. The debris is extracted from the cleaning head and collected in the filter fan unit, which cleans and re-circulates the air for a very energy efficient solution.

KELVA offers cleaning solutions for specific webs such as paper, board, non-woven tissue, corrugated, glass, laminating and many more.