ODRI PDF to print Verification and Inspection System

ODRI PDF to print Verification and Inspection System

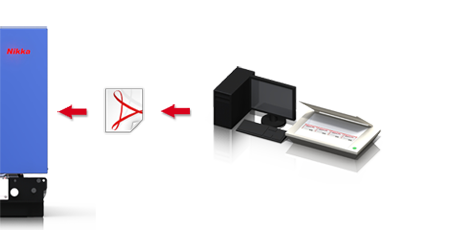

Modern label production starts with product design on the computer screen. Once approved, the design data is sent in electronic format to the printer. After many processing steps, a set of printing plates and die-cutting tools is prepared. On the printing press, these plates are capable of producing millions of labels. It is very important before and during production to verify that the printed label is identical with the customer approved design.

The Offline Digital Reference Inspection system was designed to automate the costly, time consuming and error prone visual verification of labels. The ODRI system uses a DIN A1, A2 or A3 scanner to read one print repeat of the product and automatically compares it with the PDF data used to make the plates for the product. The system automatically marks suspicious spots and highlights the differences for the operator. Inspection results are summarized in industry standard production reports for quality assurance documentation.

What can be checked ?

The ODRI systems detect typical printing defects in any language text, like broken or missing characters, ink spots, streaks, register change, die-cut deviation change. Optional inspection modules can be added to measure color, OCR, bar-code, Datamatrix and Braille verification and other special printing features.

Electronic job ticket and integration with ALIS systems

The ODRI system is designed to integrate with the ALIS camera inspection systems on printing presses and rewinders. Information from the ODRI is forwarded to the camera systems on the printing press or the rewinder for 100% inspection of the production, reducing setup time and the possibility for human error. The single reference image from ODRI assures that all labels are controlled with a traceable reference, assuring the highest possible conformity with the requirements of the print buyer.

The electronic job ticket input of the system assists quick job change and configuration. By scanning the bar-code of the factory job ticket, the system retrieves from the MIS server all product data, including prepress PDF and automatically configures all parameters. Quality managers can set inspection sensitivity in advance together with the job data.

Fast and easy to use

No computer knowledge is required from the operators of the ODRI systems. The machines are equipped with high resolution large format screens, information is displayed graphically. ODRI guides the operator through the setup and inspection process. The systems are available in all major world languages and most operators are comfortable with the system after a few hours of training.

Modular, Upgradeable and Reliable

Nikka inspection systems are based on Nikka’s 50 years of experience and innovation in the graphics industry. All machines are modular and field upgradeable for quick repair. One year remote maintenance service is included with each ODRI system. Upgrade packages will keep your Nikka inspection system competitive for years to come.

Why quality sells ?

Automatic inspection helps the QC department detect potential production problems early, analyze them objectively and take measures to correct them. Process discipline is enforced through closed loop control. Materials, time and human effort are saved, improving productivity. Accurate production costs can be calculated and responsibility is traceable. Process data reports help you show the print buyer the quality you produce. Automatic inspection helps you be more competitive!