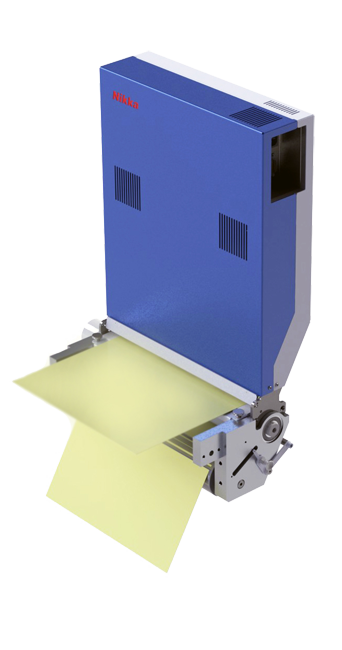

Alis L1 Inspection System

Camera inspection is a valuable tool for quality control in the roll-to-roll production of labels and flexible packaging. When installed in a slitting rewinder, the inspection system prevents defective material from reaching the end customer. The cameras on the printing press contribute to waste reduction and higher production speeds. Inspection systems also collect objective process information and supply data to production monitoring and system scheduling.

Alis L1 Modular Print Inspection Line

The Alis L1 camera family is designed to fulfill all these application requirements. It includes models for 250, 330 and 420 web widths. The compact camera block is easily installed in rewinders and printing presses. The Alis L1 uses line scan camera technology and top side LED illumination for efficient inspection of paper, transparent and highly reflective labels and unsupported film products. Color and grey scale cameras with 2K, 4K and 6K pixel resolutions are available for selecting the optimal configuration for every application. The Alis L1 is a 100% inspection camera - it scans the full width of the web without interruption and at all speeds, shows realistic live and defect images to the operator. Setup and operation are simple and intuitive - the "smart phone" style touch screen interface is easy to learn and fun to work with.

How does it work ?

Print quality inspection relies on image comparison to detect faults. A known good image is captured during setup and then all following print repeats are compared to it. Differences between the images are evaluated and flagged as faults. Inspection sensitivity is controlled by tolerances - color change, register movement and defect size. The print quality inspection system detects a variety of print defects – missing labels, remaining matrix, splices, flags, spots, fading or missing color, text defects, insects and registration. Defects are clearly displayed and signaled to the operator. On printing presses, defect images are collected for review and stored in the optional workflow database. On slitting rewinders, the camera controls the machine to slowdown and position the defect for review and repair. Inspection results are also collected in a PDF report containing production statistics, inspection settings and defect images.

Options

In addition to print quality inspection, the camera functionality can be extended using Nikka apps - program modules designed to run on the same camera platform. Apps allow the user to add new functions to the camera before and after installation and configure a "made for myself" system. The current apps collection includes: 1D and 2D Barcodes, Booklets, Color Register, Delta E, e-ticket, Geometry Check, Holograms, ISO 15416 grading, OCR, PDF Reference, Validation, Variable Data and Web viewing. Further options enhance the hardware of the system - live LED indicator for defect indication, signal tower, multi-touch monitor, dual monitor, additional lighting, reporting server and workflow.

Services

The Alis L1 product line is designed for worldwide use, maximal reliability and availability. All new systems include one year remote support and software upgrades. Using a secure Internet connection, our dedicated support team can remotely diagnose and assist you to get the maximum out of your inspection system. Support contracts with upgrade privileges help you keep your system up-to-date and competitive for years to come.