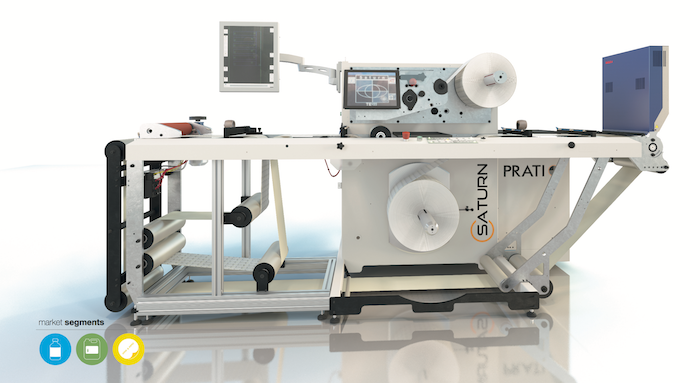

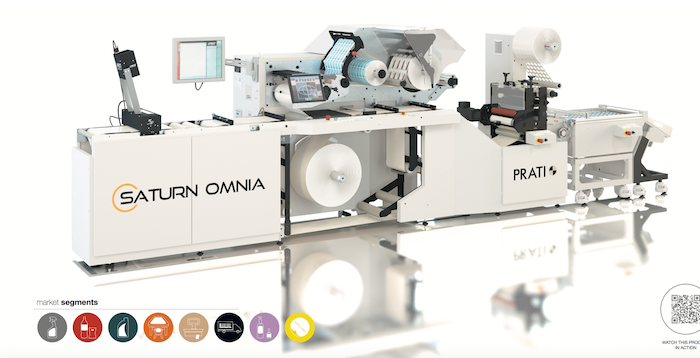

Multiuse finishing platform

The Saturn OMNIA is the ultimate multi-applications, value-for-money finishing solution. Ultimate flexibility in a compact, modular, multiuse platform for SA labels, clear-on-clear labels, cardboard, IML and flexible packaging.

The machine can be equipped with various options depending upon your market needs and Prati servo drives and SFTW ensure accurate repeatability. Ideal for handling short runs, stacking different shaped wet glue labels or In-Mould labels. High-speed switching from roll to roll, roll to sheet and roll to stack processing.