Tel : +66 2489 7115 Fax : +66 2489 7113 , Email : sales@igs.co.th

Tel : +66 2489 7115 Fax : +66 2489 7113 , Email : sales@igs.co.th

Slitting rewinders are at the end of the label production process and they are responsible for removing waste before the final product is shipped to the customer. Traditionally, rewinders are equipped with stroboscopes, missing label detectors, flag and splice sensors aimed at detecting common label production defects. These devices are difficult to adjust and rely on the attentive operator to be in working order.

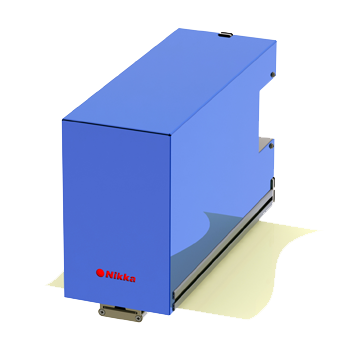

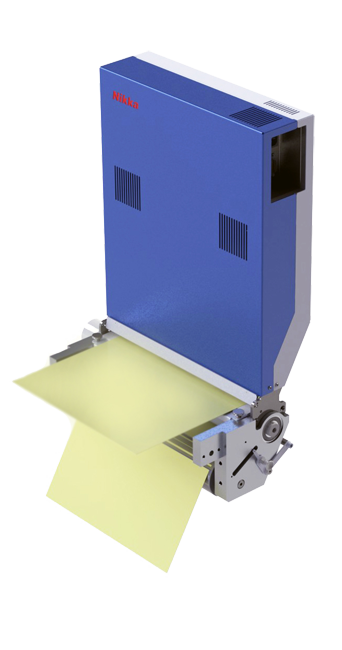

The Alis M1 uses vision technology to replace stroboscopes, counters as well as missing labels detectors and various splice and flag sensors. It integrates these functions and controls the rewinder to position faults automatically. It is designed to work with paper, transparent film and reflective materials and can inspect with speeds up to 200 m/min (M1-330) and 220 m/min (M1-440). The system consists of a small camera block and a touch monitor. It has a simple graphic interface and operation is similar to a smart phone. The operator can see a live "digital movie" image of the running web. The specially designed lighting assures a natural color view of the product, including reflective and holographic materials. Setup is automatic and most tasks are accomplished by pushing a single button.

The M1 is available in two packages - the basic system includes web viewing, counting, missing label, matrix and splice detection. The M1+ adds flag detection and basic print inspection functions. Already installed M1 systems can be later upgraded to "Plus" functions:

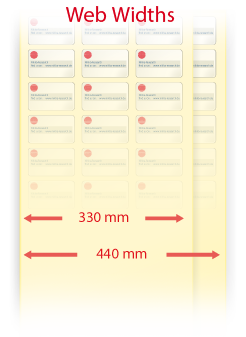

The compact Alis M1 device is available for 330 and 440 mm web widths and efficiently solves the tasks of multiple sensors and devices on a rewinder. Control functions are automatic and do not require the constant attention of the operator, freeing time for additional activities and improving the work environment. It is easy to operate, has no consumables and has an outstanding price performance.

The M1 product line is designed for worldwide use, maximal reliability and availability. All systems include one year remote support and software upgrades. Using a secure Internet connection, our dedicated support team can remotely diagnose and assist you to get the maximum out of your inspection system. Support contracts with upgrade privileges help you keep your system up-to-date and competitive for years to come.

Camera inspection is a valuable tool for quality control in the roll-to-roll production of labels and flexible packaging. When installed in a slitting rewinder, the inspection system prevents defective material from reaching the end customer. The cameras on the printing press contribute to waste reduction and higher production speeds. Inspection systems also collect objective process information and supply data to production monitoring and system scheduling.

The Alis L1 camera family is designed to fulfill all these application requirements. It includes models for 250, 330 and 420 web widths. The compact camera block is easily installed in rewinders and printing presses. The Alis L1 uses line scan camera technology and top side LED illumination for efficient inspection of paper, transparent and highly reflective labels and unsupported film products. Color and grey scale cameras with 2K, 4K and 6K pixel resolutions are available for selecting the optimal configuration for every application. The Alis L1 is a 100% inspection camera - it scans the full width of the web without interruption and at all speeds, shows realistic live and defect images to the operator. Setup and operation are simple and intuitive - the "smart phone" style touch screen interface is easy to learn and fun to work with.

Print quality inspection relies on image comparison to detect faults. A known good image is captured during setup and then all following print repeats are compared to it. Differences between the images are evaluated and flagged as faults. Inspection sensitivity is controlled by tolerances - color change, register movement and defect size. The print quality inspection system detects a variety of print defects – missing labels, remaining matrix, splices, flags, spots, fading or missing color, text defects, insects and registration. Defects are clearly displayed and signaled to the operator. On printing presses, defect images are collected for review and stored in the optional workflow database. On slitting rewinders, the camera controls the machine to slowdown and position the defect for review and repair. Inspection results are also collected in a PDF report containing production statistics, inspection settings and defect images.

In addition to print quality inspection, the camera functionality can be extended using Nikka apps - program modules designed to run on the same camera platform. Apps allow the user to add new functions to the camera before and after installation and configure a "made for myself" system. The current apps collection includes: 1D and 2D Barcodes, Booklets, Color Register, Delta E, e-ticket, Geometry Check, Holograms, ISO 15416 grading, OCR, PDF Reference, Validation, Variable Data and Web viewing. Further options enhance the hardware of the system - live LED indicator for defect indication, signal tower, multi-touch monitor, dual monitor, additional lighting, reporting server and workflow.

The Alis L1 product line is designed for worldwide use, maximal reliability and availability. All new systems include one year remote support and software upgrades. Using a secure Internet connection, our dedicated support team can remotely diagnose and assist you to get the maximum out of your inspection system. Support contracts with upgrade privileges help you keep your system up-to-date and competitive for years to come.

Automatic Label Inspection Systems help significantly reduce waste during printing. The ALIS camera systems check every label passing through the slitting rewinder, detecting printing mistakes at speeds up to 320 m/min. The rewinder is then controlled to slow down and position the defect for viewing. The image of the defect is clearly displayed on the screen and the operator can quickly repair it by replacement or splice-out. On pharmaceutical rewinders, the repaired segment can be re-inspected. PDF verification technology is used to automate setup and assure one point of reference. Statistical information is collected and organized in easy to read, graphical reports. The 100% inspection assures that no printing defects reach the print customer.

Automatic inspection works by comparing a known good image, called “reference” with the image of each label. The reference image can be taken from the material, from a previous job or from a digital prepress PDF file. During inspection, the camera system compares the reference image with the print, allowing for process deviations like colour change, register and die-cutter moves. When the deviation exceeds a set tolerance, ALIS signals the host machine to stop and shows the operator the position of the defect and the possible cause.

The ALIS system detects typical printing defects like color change, broken or missing print, ink spots and streaks, register change, matrix, splices and missing labels. Optional inspection modules can be added to check variable printing, bar codes, Datamatrix, security features and make special measurements.

The automatic illumination of the ALIS-L inspection system adapts to practically all types of substrates and processes. Special finishing like hot and cold foil, embossing, metalized substrates and transparent films can be reliably inspected.

The electronic job ticket input of the system assists quick job change and configuration. By scanning the bar-code of the factory job ticket, the system retrieves from the MIS server all product data, including prepress PDF and automatically configures all parameters. The operator must only command the system to start inspection. Quality managers can set inspection sensitivity in advance together with the job data. With the full job information, the inspection system can also prevent a number of finishing mistakes.

The high resolution, high quality image of the system assists the operator in monitoring the web. Defects are clearly indicated and the operator can quickly identify and repair them. The automatic inspection frees the operator from constantly monitoring the web and reduces eye strain.

No computer knowledge is required to operate a Nikka system. The machines are all equipped with a touch screen, information is displayed graphically and buttons are operated by touching the screen. No mice or keyboards are needed. The machine guides the operator through each procedure. Image on screen exactly matches the image on paper. ALIS systems are available in all major world languages and most operators are comfortable with the system after e few hours of training.

ALIS L systems are available for three web widths – 330 mm, 420 mm, 560 mm, 620 mm and 760 mm. The L2 model is available for new rewinders and as retrofit module. The system can be fitted to all popular rewinders. The Alis L2 is highly customizable with Barcode, Variable Data and OCR optional modules. The machine is available with precision CCD black and white and color cameras with resolutions 2K, 4K, 6K and 8K depending on the application.

Nikka inspection systems are based on Nikka’s 50 years of experience and innovation in the graphics industry. All machines are modular and field upgradeable for quick repair. One year remote maintenance via secure Internet connection and upgrades is included with each L2 or C2 system. Upgrade packages help keep your Nikka inspection system competitive for years to come.

Automatic Label Inspection Systems help significantly reduce waste during printing. The ALIS camera systems check every label passing through the printing press, detecting printing mistakes at speeds up to 180 m/min. The operator is alerted of the change and can quickly correct the problem. PDF verification technology is used to automate setup and assure one point of reference. Process information is collected, allowing accurate quality and cost analysis. The printer knows accurately how many good meters are in the ready roll. The risk of reprints is eliminated and the reserve meters can be reduced. Statistical information is collected and organized in easy to read, graphical reports.

Automatic inspection works by comparing a known good image, called “reference” with the image of each label. The reference image can be taken from the material, from a previous job or from a digital prepress PDF file. During inspection, the camera system compares the reference image with the print, allowing for process deviations like colour change, register and die-cutter moves. When the deviation exceeds a set tolerance, ALIS signals the operator, showing the position of the defect and the possible cause.

The ALIS system detects typical printing defects like color change, broken or missing print, ink spots and streaks, register change, matrix, splices, missing labels. Optional inspection modules can be added to check variable printing, bar codes, security features and make special measurements.

The automatic illumination of the ALIS-L inspection system adapts to practically all types of substrates and processes. Special finishing like hot and cold foil, embossing, metalized substrates and transparent films can be reliably inspected.

The electronic job ticket input of the system assists quick job change and configuration. By scanning the bar-code of the factory job ticket, the system retrieves from the server all product data, including prepress PDF and automatically configures all parameters. The operator must only signal the system when the desired print quality is achieved. Quality managers can set inspection sensitivity in advance together with the job data. With the full job information, the inspection system can accurately display printed “good meters”.

The high resolution, high quality image of the system assists the operator in monitoring the printing process. On the optional second monitor several enlarged views of the web can be displayed at different magnifications. This is a great tool for simultaneous monitoring of color register at both edges of the web, overprint areas and die-cut register. The advanced defect trend and press analysis module assists the operator in the early identification of printing problems. The optional “traffic light” style indicator will alert the operator even if he is not in front of the inspection system. After completion of the job, an itemized report with all important statistics gathered during the print is saved in PDF format.

No computer knowledge is required from the operators of Nikka systems. The machines are all equipped with a touch screen, information is displayed graphically and buttons are operated by touching the screen. The machine guides the operator through each procedure. Image on screen exactly matches the image on paper. ALIS systems are available in all major world languages and most operators are comfortable with the system after e few hours of training. No mice or keyboards need to be mounted on the printing machine.

ALIS L systems are available for three web widths – 330 mm, 420 mm, 560 mm, 620 mm and 760 mm. The L2 model with its compact form fits on most printing presses and is available for both new presses and as retrofit. The Alis L2 is highly customizable with Barcode, Variable Data and OCR optional modules. The machine is available with precision CCD color cameras with resolutions 2K, 4K, 6K and 8K depending on the application. Workflow systems (inspect on press, repair on rewinder) are supported with recording defect coordinates in a roll map and controlling process down-stream equipment (turrets, slitter rewinders) to eject the waste sections.

Nikka inspection systems are based on Nikka’s 50 years of experience and innovation in the graphics industry. All machines are modular and field upgradeable for quick repair. One year remote maintenance and upgrades is included with each L2 or C2 system. Upgrade packages help keep your Nikka inspection system competitive for years to come.

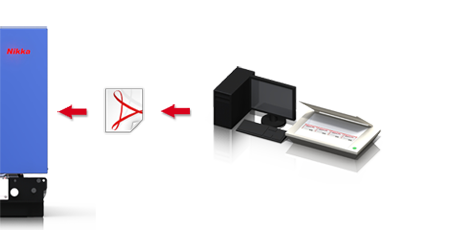

Modern label production starts with product design on the computer screen. Once approved, the design data is sent in electronic format to the printer. After many processing steps, a set of printing plates and die-cutting tools is prepared. On the printing press, these plates are capable of producing millions of labels. It is very important before and during production to verify that the printed label is identical with the customer approved design.

The Offline Digital Reference Inspection system was designed to automate the costly, time consuming and error prone visual verification of labels. The ODRI system uses a DIN A1, A2 or A3 scanner to read one print repeat of the product and automatically compares it with the PDF data used to make the plates for the product. The system automatically marks suspicious spots and highlights the differences for the operator. Inspection results are summarized in industry standard production reports for quality assurance documentation.

The ODRI systems detect typical printing defects in any language text, like broken or missing characters, ink spots, streaks, register change, die-cut deviation change. Optional inspection modules can be added to measure color, OCR, bar-code, Datamatrix and Braille verification and other special printing features.

The ODRI system is designed to integrate with the ALIS camera inspection systems on printing presses and rewinders. Information from the ODRI is forwarded to the camera systems on the printing press or the rewinder for 100% inspection of the production, reducing setup time and the possibility for human error. The single reference image from ODRI assures that all labels are controlled with a traceable reference, assuring the highest possible conformity with the requirements of the print buyer.

The electronic job ticket input of the system assists quick job change and configuration. By scanning the bar-code of the factory job ticket, the system retrieves from the MIS server all product data, including prepress PDF and automatically configures all parameters. Quality managers can set inspection sensitivity in advance together with the job data.

No computer knowledge is required from the operators of the ODRI systems. The machines are equipped with high resolution large format screens, information is displayed graphically. ODRI guides the operator through the setup and inspection process. The systems are available in all major world languages and most operators are comfortable with the system after a few hours of training.

Nikka inspection systems are based on Nikka’s 50 years of experience and innovation in the graphics industry. All machines are modular and field upgradeable for quick repair. One year remote maintenance service is included with each ODRI system. Upgrade packages will keep your Nikka inspection system competitive for years to come.

Automatic inspection helps the QC department detect potential production problems early, analyze them objectively and take measures to correct them. Process discipline is enforced through closed loop control. Materials, time and human effort are saved, improving productivity. Accurate production costs can be calculated and responsibility is traceable. Process data reports help you show the print buyer the quality you produce. Automatic inspection helps you be more competitive!

Head Office :

iGS Innovative Graphics Solution : The Terrace 1088/5-6 Petkaem 63 Alley Phetkasem Rd. Laksong Bangkae Bangkok Thailand

Tel : +66 2489 7115 Fax : +66 2489 7113 Email : sales@igs.co.th

Showroom :

iGS Innovative Graphics Solution : 59/46-47 Moo 12. Petkaem 120 Alley Phetkasem Rd. Omnoi Kratumban Samutsakorn Thailand 74130

Tel : +66 2489 7115 Fax : +66 2489 7113

Email : sales@igs.co.th