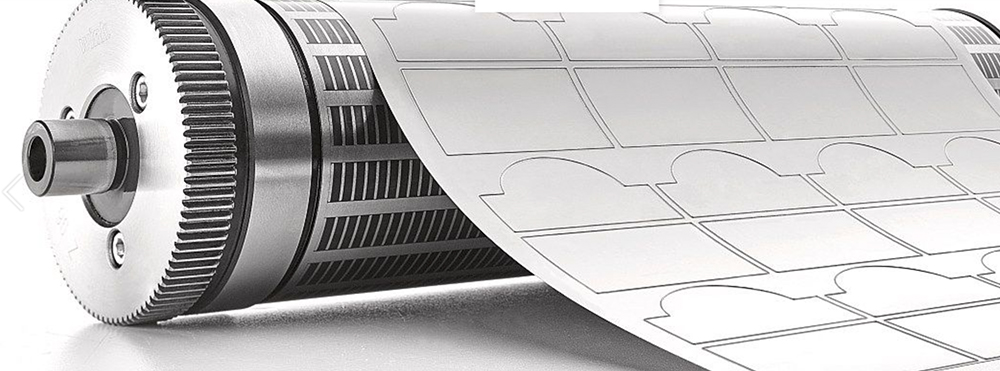

MAXIMUM PERFORMANCE

Our SuperCut dies make convincing products because of their very high operating performance even in the basic versions. For certain materials and applications, however, it makes sense to increase the lifetime of a tool even further through special types of finishings. The flexibility, tolerance and magnetic adhesion of the dies remain fully preserved with all coatings and hardening processes.

OVERVIEW OF VARIANTS

- Laser hardening is generally recommendable for cutting-through as well as for difficult-to-cut filmic materials in large quantities.

- MC coating offers very good protection against wear when die-cutting abrasive (thermal) materials.

- Particularly in the processing of very abrasive materials and inks (thermal paper, opaque white, luminous paints) in long runs, the MCR coating offers a considerable prolongation of lifetime, also in combination with laser hardening.

- Especially with particularly “extreme” materials and very large quantities, MC plus coating prolongs the service life of the flexible die to a maximum.

- Our four non-stick coatings are the optimum solution if you are combating ink and adhesive residues. The non-stick coating minimises these residues on the cutting edges and on the surface of the die, thus ensuring an undisturbed production process